As we look back at 2025, it is easy to surmise that the US disposable glove market has been volatile but resilient, driven by strong demand across healthcare, industrial, and personal care sectors despite economic headwinds and the impact of tariffs on imports.

Global consumption of nitrile gloves, the most popular material, has surpassed 400 billion gloves, with Southeast Asia continuing to supply over 80% of the worldwide output. At the same time, the US domestic production remains minimal due to high production costs and scalability challenges.

Overall, tariffs, logistics, and supply chain have impacted the 2025 disposable glove market in ways rarely seen before. Despite pricing pressures, demand remains resilient, and the need for disposable gloves continues to grow.

Tariff Impact

Sweeping U.S. tariffs on imported gloves have had a substantial impact on sourcing. Since their introduction earlier in 2025, import tariffs on disposable gloves now range between 19% and 70%, with Chinese disposable gloves facing an additional 50% hike on January 1st, 2026.

These tariffs have shifted demand toward Southeast Asia (Malaysia, Vietnam, Indonesia), while Chinese suppliers have lost competitiveness in the US market.

Pricing Trends

Naturally, prices on disposable gloves are rising due to several factors. Outside of tariffs, higher raw material costs (especially NBR for nitrile gloves), increased logistics costs from port congestion, container shortages, and energy price volatility all contributed to price impacts in 2025. Spot orders and short-term sourcing continue to be risky; strategic sourcing and long-term contracts are recommended.

Logistics & Supply Chain

Shipping lanes from Southeast Asia to the U.S. were subject to volatile freight rates in 2025. US domestic freight costs are rising due to labor shortages and compliance costs. Environmental regulations on shipping have slowly been further adding to cost pressures.

Demand Outlook

Despite all the dynamic challenges outlined above, demand for disposable gloves remains steady and recession-resistant, especially in healthcare and industrial sectors. Buyers are advised to plan and maintain strong supplier relationships to mitigate risk.

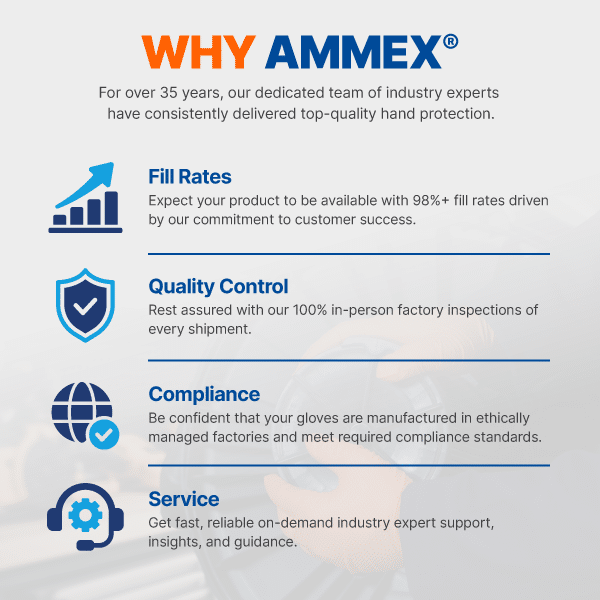

Throughout 2025, AMMEX continued to proactively work to mitigate the impact of market conditions on our partners. Looking forward, we will continue to evaluate the market and update our partners on any changes in market conditions.